Thanks to everyone who came to the last pedal building workshop at Noisebridge. I was impressed with the enthusiasm! We demoed some pedals talked about populating the PCB and identifying the correct parts and placing them in the correct locations on the PCB and soldering.

The next workshop is scheduled for Saturday, March 4th, 1 to 3 PM. Sign up on Meetup.com. You should go!

The next session will cover any questions or problems that may have come while populating the PCB and how to put it all in a box.

Boxing up the effect requires finding a suitable enclosure, one that fits the PCB, pots, and jacks, and wiring it all together.

many of the people from the workshop wanted to build this tremolo. I had these boards made at PCBWay.com. Let me know if anyone is interested in designing an manufacturing your own PCBs and we could make that a topic for an upcoming workshop session.

Boxes

You can put a pedal into just about anything. Most popular are these hammond enclosures. Used by MXR and many of the boutique pedal makers today.

These boxes come in a couple standard sizes. The three most common sizes are:

- 1590B (Tayda, LoveMySwitches, StompBoxParts)

- 1590BB (Tayda, LoveMySwitches, StompBoxParts)

- 125B (Tayda, LoveMySwitches, StompBoxParts)

I included links to where you might buy these online. You can also get these at many other places. They come in almost any color and bare metal (which is cheapest.)

What’s the difference between these? The 1590B is the smallest and is the size of the classic MXR pedals. MXR and others use this box still.

125B is a little bit bigger in all dimensions that the 1590B. Lot of builders like this because it provides a little more room to fit components. With this box you can also place the jacks at the top of the box which is a popular option.

1590BB is wider than the other two, though not as tall as the 125B. This box is good for larger PCBs.

Many professional pedals use the same enclosures!

Here are a few other sizes that are available. The images below show a range of the enclosures that you can buy.

Other boxes

There are many other sizes and variations of the boxes listed above. You can also use anything you find around the house, in the trash, or the thrift store. Really anything that will fit the PCB, jacks, and switch.

Two important ideas when looking for a custom enclosure. It needs to be sturdy enough for you to step on it with your foot, if you plan to use it as a floor pedal, and it’s best if it is made of metal to prevent noise interference from outside.

Drilling the box

You’ll need to drill the box. While the boxes are made of metal, it’s pretty soft and can be drilled with standard drill bits. Noisebridge has a drill press which is great for this drilling boxes. You can also use a hand drill. I’m not sure what type of drill bits they have available, you might have to bring your own bits.

Standard drill bits work fine. These stepped bits are good and will drill all of the different hole sizes with out having to change bits. With one of these bits you could some or all of the holes in an enclosure.

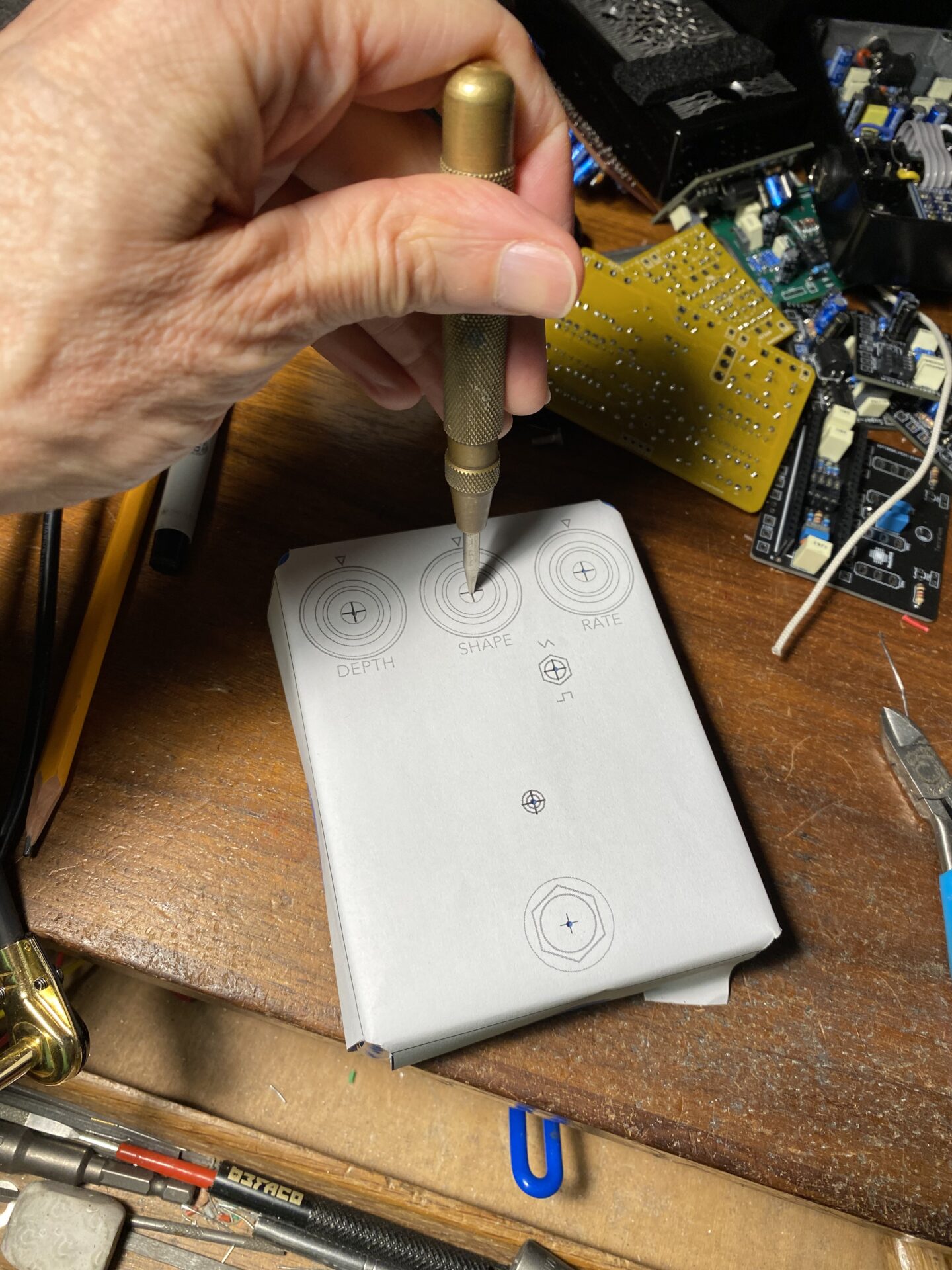

You’ll need to drill the holes in the right locations. An easy way to do this is to wrap the box in a paper template, secure it with some tape and drill through the templates.

You can also mark the holes with a punch through the template, remove the pager template and then drill.

Alternately you can drill through the paper! This works but beware! If you have a painted enclosure the metal bits from the drill will get under the paper and scratch the paint.

What size holes do you need to drill?

- The pots are usually 1/4″ 8mm

- Think about the size of the LED you will be using. The two most common sizes 3mm and 5mm. Drill LED hole at size of the LED you will use.

- If your box has a toggle switch check the size. These are usually smaller than the pots. About 3/16″ or 5mm.

It’s a good idea to think about the sizes you will drill before drilling. You can even write them on the template to remind you as you drill!

Putting it in the box

Once you have the holes drilled and your PCB completed, but you still haven’t soldered the pots and the LED you’re ready to assemble everything. Follow these steps:

- Put the pots and the LED into the PCB without soldering.

- Fit the pots and the PCB into the box and put a nut and washer on each of the pots.

- Maneuver the LED into its hole from the back.

- With everything in place solder the pots and LED from the back of the box.

Using this approach guarantees that all of the pots will be square to the enclosure and align with the holes and the LED is right distance from the PCB to fit its hole in the box.

Wiring

You’ll need to wire the foot switch, the input and output jacks, and the power jack.

3PDT Foot Switch

The foot switches have three poles, it’s like there are three switches inside. Two of the switches are used to switch the input and output jacks and the third is used to switch the LED on and off.

The 3PDT name stands for 3 pull/pole Double Throw. You can get these all over, even on Amazon. Tayda, Stompboxparts, and LoveMySwitches have plenty of options.

See the diagram below of the 3PDT switch.

The row in the enter is the, note the flat side. In one position the center lugs connect with the bottom row, and where the switch is in the other position the center lugs connect to the top row.

Jacks

There are plenty of different jacks. For the most part all of these jacks are good some are smaller and might fit a tight space better than another.

You will need two 1/4″ jacks for the instrument input and output, and a 2.1mm jack DC power jack.

Some common 1/4″ style jacks. You should mono jacks for the input and output.

For power you need a 2.1mm DC power jack. These come in a couple styles. I like that small one on the left.

Here are some links to jacks:

- 1/4″ jacks at Tayda Stompboxparts LoveMySwitches

- DC jacks Tayda Stompboxparts LoveMySwitches

Wiring

Here is how you will wire the switch.

Here is the general wiring diagram for the 3PDT switch. This the foot switch that engages or bypasses the circuit. The wiring handles turning on the LED when the effect is engaged. When circuit is bypassed the input signal goes from the input jack to the output jack directly, people call this “True Bypass.”

Here is how the signal flows through the switch.

Challenge! Take a look at the center pole. This handles the LED. Can you see how the LED is connected to GND when the effect is engaged and not connected to GND when the effect is bypassed?

conclusion

Use the ideas from this post to drill your enclosure and wire the switch and jacks to the circuit board.

Leave a Reply