This is post for anyone interested in getting started making your own guitar pedals and prototyping your own PCBs.

I like making guitar pedals and synth modules. I’ve built more than a few of each. When I started, some of the first modules I built were done on perf-board and strip-board, then I moved to making making the PCBs myself. At the time I started, the cost of having boards manufactured was very expensive, and you were required to buy a complete run of boards, usually 50 to 100 pieces. Even at a dollar or two a piece that can get pretty expensive and leave you with a lot of unused PCBs.

Over the last few years the cost of manufactured PCBs has come down and many companies offer a prototyping service which allows you to buy a small number of boards at a low cost.

Prototyping with a manufactured PCB has many advantages. You can develop your boards in software, which may not sound exciting, but provides many advantages like: error checking and confirmation. The traces sizes allowed are much smaller which allows for tighter and more organized boards. Two layer boards are easy to make and easier to design for. Solder masking makes boards easier to assemble and look great. Plate through holes and pre-tinning make boards easy to assemble and durable. Parts and labels are clearly marked with a silkscreen layer on front and back. No mess, you don’t have to deal with chemicals and the etching process. Working with professionally manufactured boards is a big advantage.

There might be some advantages to home made boards but they are far out weighed by the avalanche of positives from manufactured boards. Seriously, this is the way to go even if you are just experimenting. If your time is valuable putting a little money into some professionally manufactured boards is worth it.

There has to be a drawback? Since you’re not doing the work yourself at home you’ll have to place an order, pay the manufacturer, and wait for delivery. If you make a mistake in your design then you’ll receive board with a mistake.

How to make boards?

You’ll need some software. I use Eagle PCB, they have free tier which works fine for small boards and has worked for everything that I have done so far. It’s easy to get started with and there is a lot of support available.

Kicad is another choice. It is an open source and free tool developed by the community. Kicad works, has a lot of options and support.

There are a few concepts that are common to all PCB software. These are the schematic symbols and footprints. Schematic drawings are made from abstract symbols while the actual board will be built from real world objects that take up space and have pins in very specific locations.

You’ll build a schematic of your project describing how all of the parts will be connected. The software will give you a board layout with all of the parts using the footprints associated with those parts.

The software also provides a rats nest of connections. This shows how all of the parts connect based on your schematic. At this point it’s your job to draw the traces between each part following the rats nest. Eagle has an auto router function that will Draw traces for you.

The process starts to become more about the design of the project than about overcoming manufacturing challenges, this allows you to concentrate on making a better product.

Also, Using a manufactured two layer board you can fit more more parts into a smaller space. This helps you move from prototype to the product you are envisioning faster.

I recommend installing these libraries of symbols and footprints which contain parts common for guitar pedals.

The libraries here will give you a good collection of parts that can be used to build almost any guitar pedal you might think of.

Understand that designing boards with Eagle or Kicad includes a learning curve! It will take some time to get oriented with the software. Start small, after time you will be able to do more!

Design Rules

I haven’t included a tutorial here since the subject would require one or more dedicated posts! If there is interest post a comment. If there is enough interest it could happen in the future!

When you’ve got your design finalized be sure to check it with your software. Eagle has a Design Rules Check. Running this will tell you if your design meets the requirements of the rules you have set. You’ll need to set the rules and these will differ depending on where you have your board manufactured.

You can download Design Rules File here and import it into Eagle. After importing this and running the Design check Eagle will tell you if and where your design meets the specifications.

Manufacturing PCBs

Once you’ve got your design completed and checked you need to export the files that can be manufactured. Follow the guide here.

If you’d like to confirm what your design might look like when manufactured PCBWay has a nifty Gerber viewer. Import the files you generated in the last step here. With this tool you can look at each of the layers that will be generated and visually confirm they are what you are expecting.

When you’re ready upload your designs to PCBWay.com. Their prototyping service is very reasonable. The cost is $5 for 10 boards (it costs the same to order 5 boards, always order 10!) The price jumps if your boards are larger 100mm. If it’s possible to keep your design under 100mm do it!

The biggest cost, for me, is shipping. I’m in the US and PCBWay.com ships from China. The best way I have found to balance the cost of shipping is to place multiple orders together. PCBWay will gang shipping which reduces costs. If you’re planning to make two or more designs ordering these at the same time will save money!

After placing your order your design will be reviewed. This process finds production errors but it won’t find mistakes in design. If an error occurs you’ll be asked to fix it and upload an update.

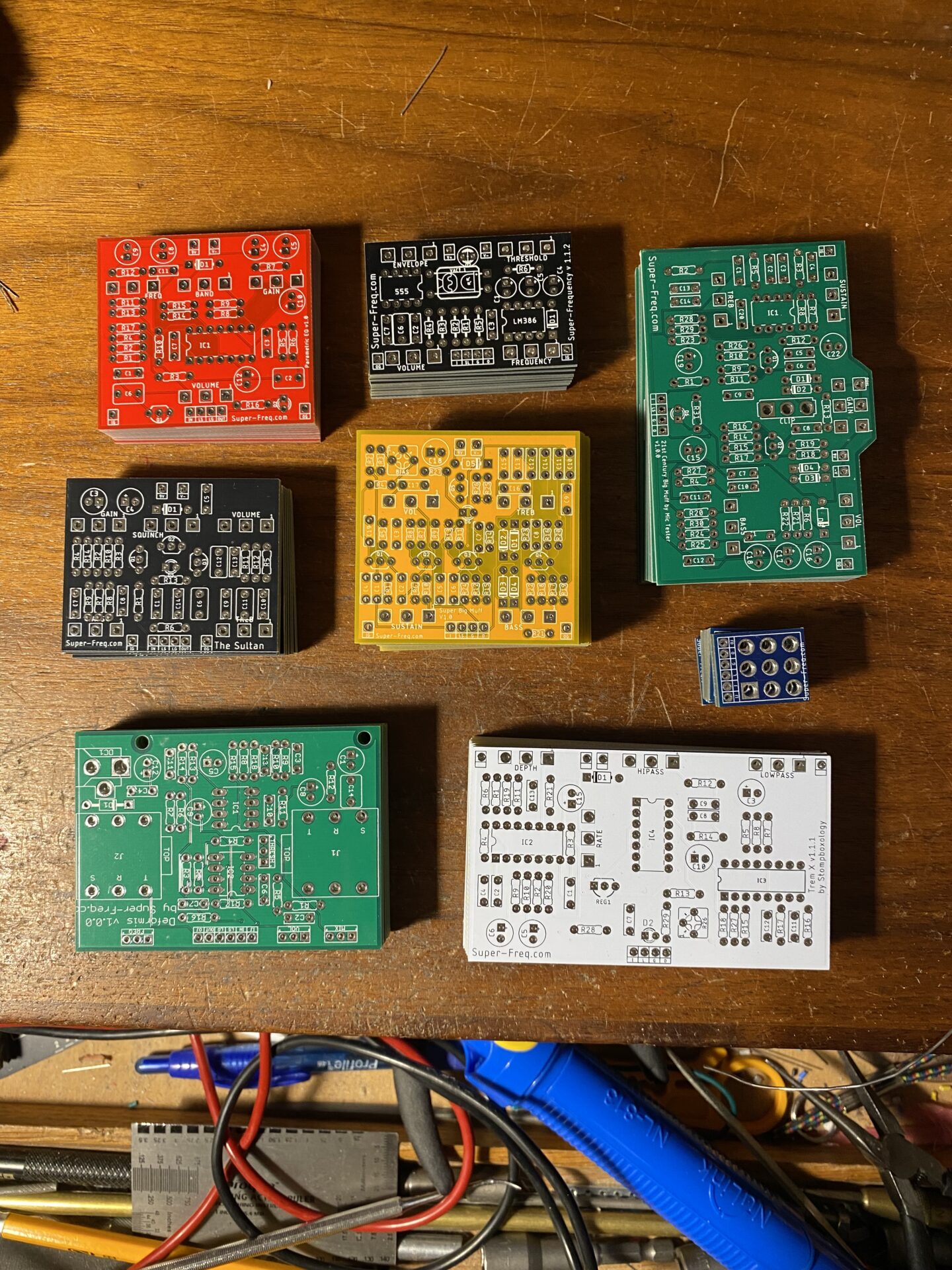

The last step is to wait for PCBs to ship to you. If you’re curious about the quality or would like to see more examples take a look at my blog. I have used the service for a year now and have made many PCBs through PCBWay.com and have always been happy with the results. I have documented all of my projects with pictures and notes!

Leave a Reply