Tag: Fuzz

-

Summon Fuzz

I built this a few years ago. I got it out and played it for a while. sounds pretty good. This is a Big Muffin with a diode lift switch, and a blend control. The PCB is from https://shop.pedalparts.co.uk/product/bassblendmuff. It worked well but the board doesn’t have an LED! So the wiring is a little…

-

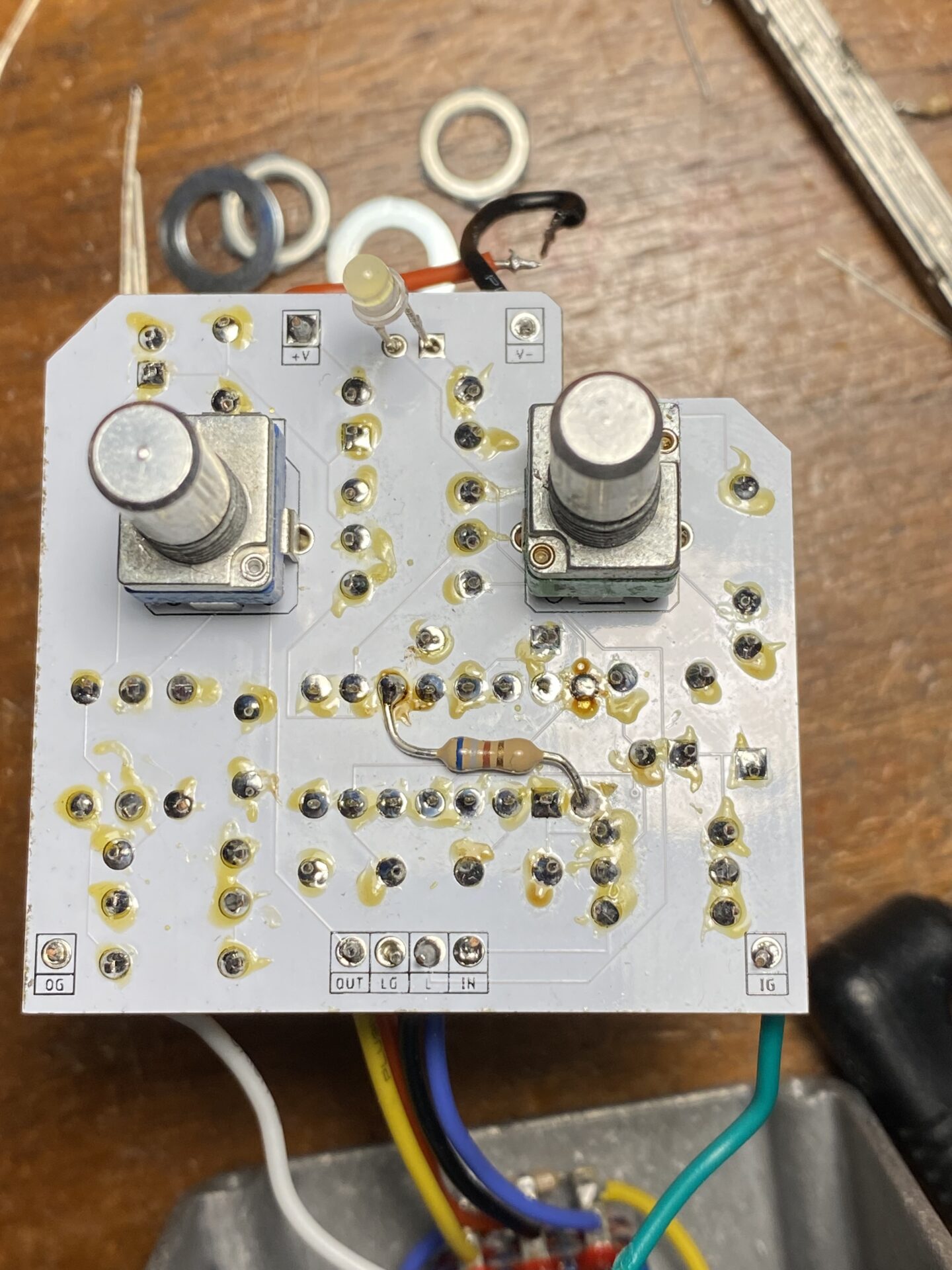

Deformis: Ugly Face with Mix mod

This is my take on Tim Escobedo’s Ugly Face. I replaced the LM386 with a dual op-amp and and added a mix control. The LM386 is a great chip but its gain is limited to 200. A single op-amp can easily generate a gain of 200 and more! This way I can replace the 386…

-

Another Super Fuzz!

Another Super Fuzz build. I used the first PCB I designed from a post over at FreeStompBoxes.org, read about that first build here. This one looked good but it didn’t work! I put it aside because the problem wasn’t obvious. I got it out again and set at debugging. After a few minutes with the…

-

Retro Channel: The Fuzz Clone

The Fuzz by Retro Channel is a Fuzz circuit built around the CA3046 transistor array. It’s a lot like a Fuzz Face and Tone Bender. It makes use of all of the transistors on the CA3046 and sounds pretty good doing it. Here is a schematic I found over at https://www.freestompboxes.org/viewtopic.php?t=13062 Q3 and 4 are…

-

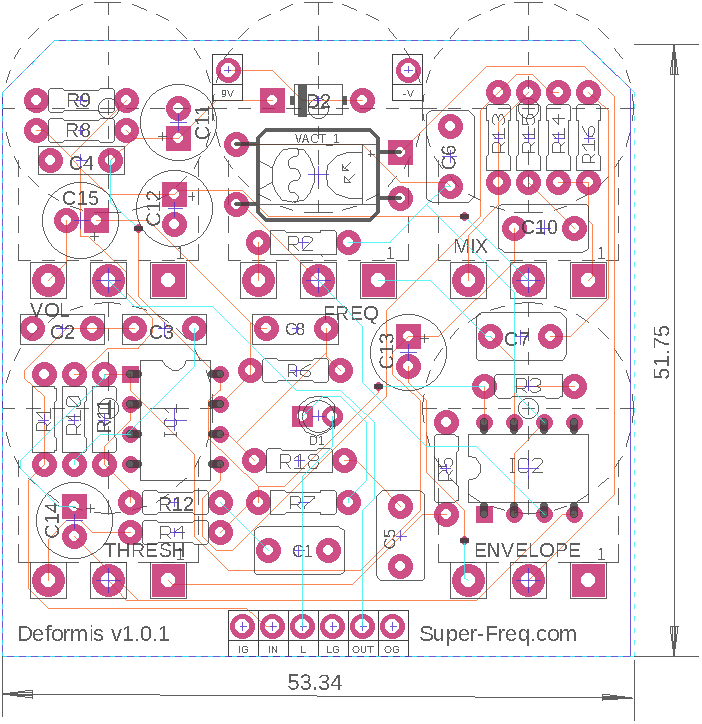

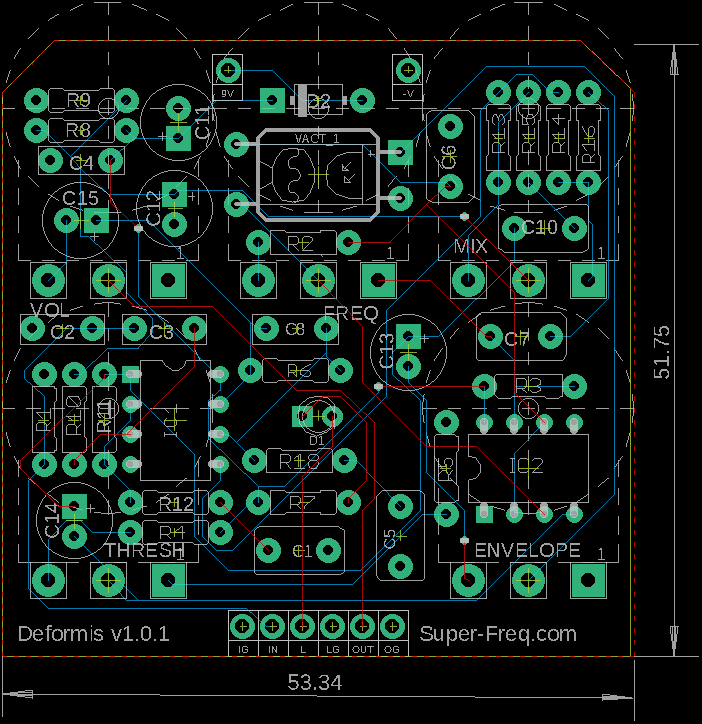

Deformis – Ugly Face with a mix control

Here is an updated post with a schematic and parts for the Deformis. This started as Tim Escobedo’s Ugly Face. I made a few changes. I swapped the LM386 with a dual op-amp. The 386 was used in the Ugly Face as an amplifier with a gain of 200, a single op-amp can easily replace…

-

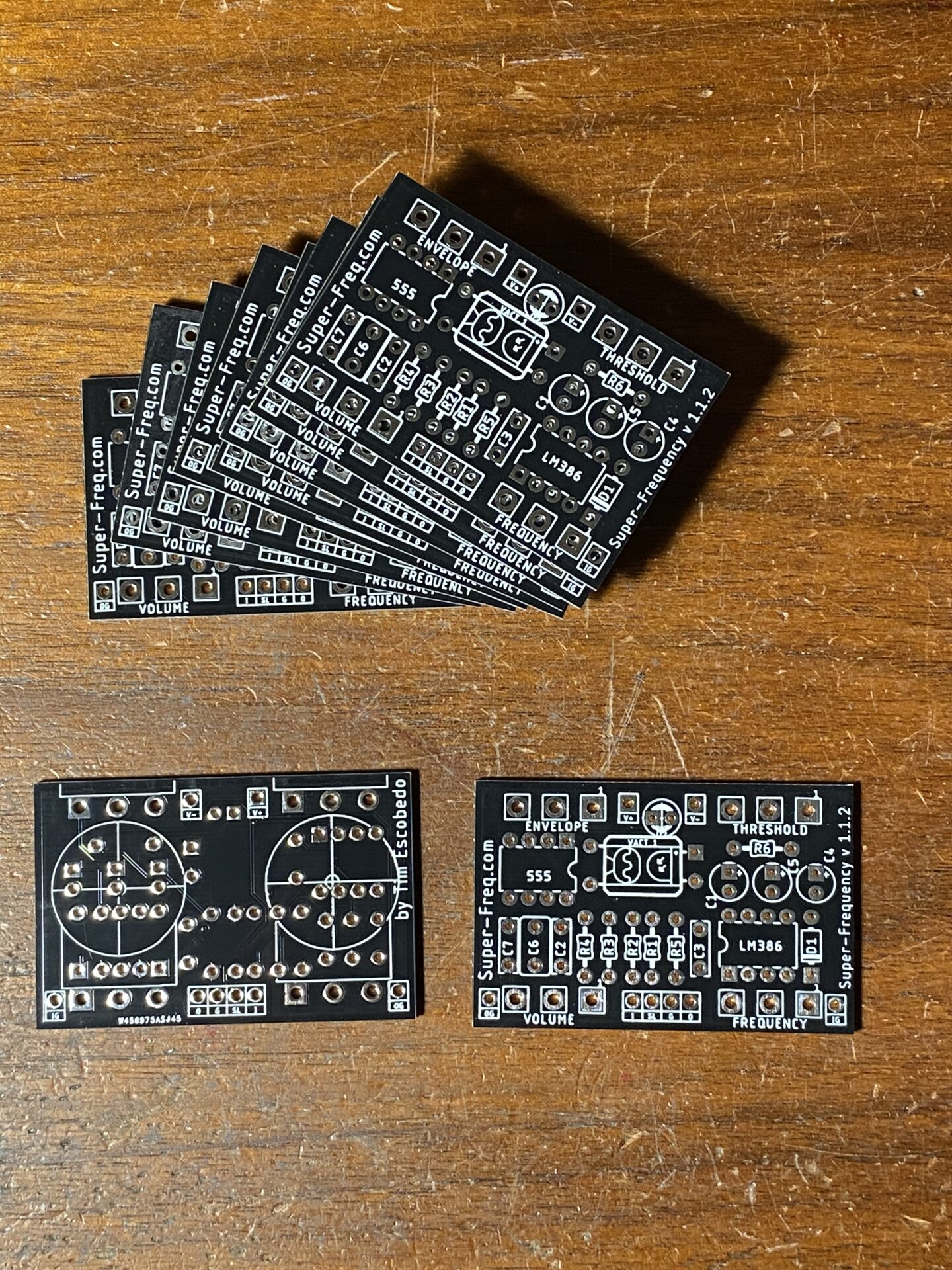

Super Frequency

This is my spin on Tim Escobedo’s Ugly Face. The original is a great DIY project anyone that hasn’t built it should give it a try. Super fun, unique sound, parts are easy to get, and it’s not a difficult built. This version makes a few changes to the original. The original uses an LM386…

-

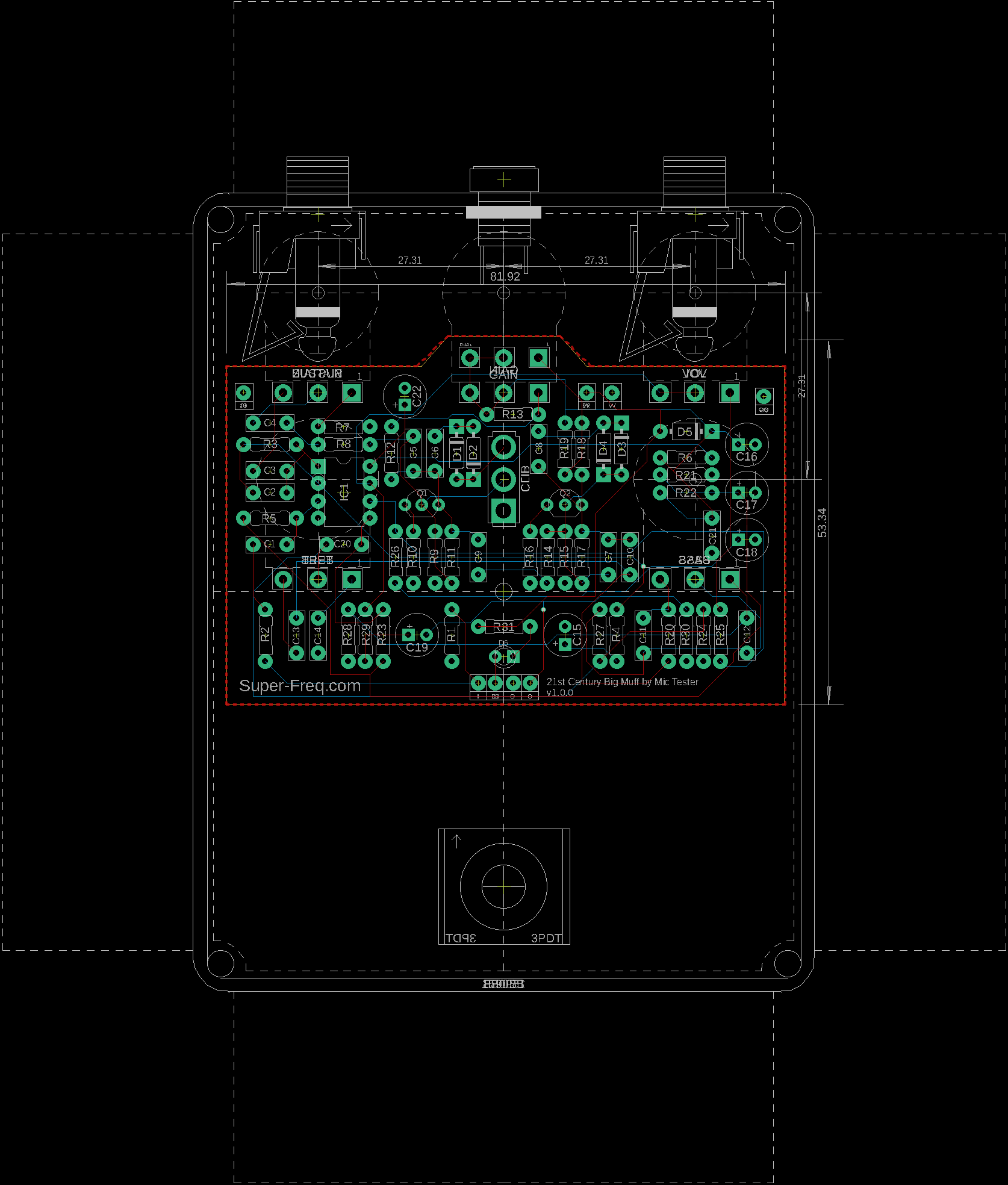

Bigger Muff part 2

Looking at the Bigger Muff. Still not happy with this, it doesn’t sound bad it’s just that the range of the controls is unsatisfying. There are plenty of usable sounds some but some of the settings are not useful. Here is the schematic: Here is a BOM: Partlist: BASS A1M 16MM GAIN A100k 16MM_DUALSUSTAIN A100k…

-

Peach Fuzz Clone

I have wanted to try the Frantone Peach Fuzz for a long time. The circuit uses one of my favorite chips the LM386. Not only does it use the 386 it uses two in series. Frantone is one of the original boutique companies, starting in 1994! They went dormant for a some years but have…

-

Ugly Face Build

The Ugly Face is a classic DIY Stompbox build. Almost a rite of passage! The circuit, by Time Escobedo, has been around since late 2002! Here is my schematic. Schematic Parts List Part Number Value R1 1M (Tayda, Stompboxparts) R2 470 (Tayda, Stompboxparts) R3 100K (Tayda, Stompboxparts) R4 22k (Tayda, Stompboxparts) R5 1k (Tayda, Stompboxparts)…

-

Super Fuzz Build!

Build your own Super Fuzz! The Super Fuzz is an octave fuzz used by Pete Townsend, Muddy Honey, J. Mascis and others. Read this post to learn more about the Super Fuzz. Build Your Super Fuzz Here is the schematic for the Super Fuzz. Note! There are several versions and schematics vary. This schematic matches…

-

Ugly Face with Mix

I’m a big fan of the Tim Escobedo’s Ugly Face. This is a super fun project, sort of a. right of passage for DIY pedal makers. The sound is unique. The best way to describe it is as a square wave oscillator that hard syncs to the guitar signal. Since the output is either on…

-

Stone Bender #3

This sounds really good. I figured I’d build another and give to a friend, trade it, or try and sell it on Reverb. I made one of these on strip board and sold it at a swap meet. Here’s a post about the original circuit and schematic. I made an updated PCB check out the…