Tag: Fuzz

-

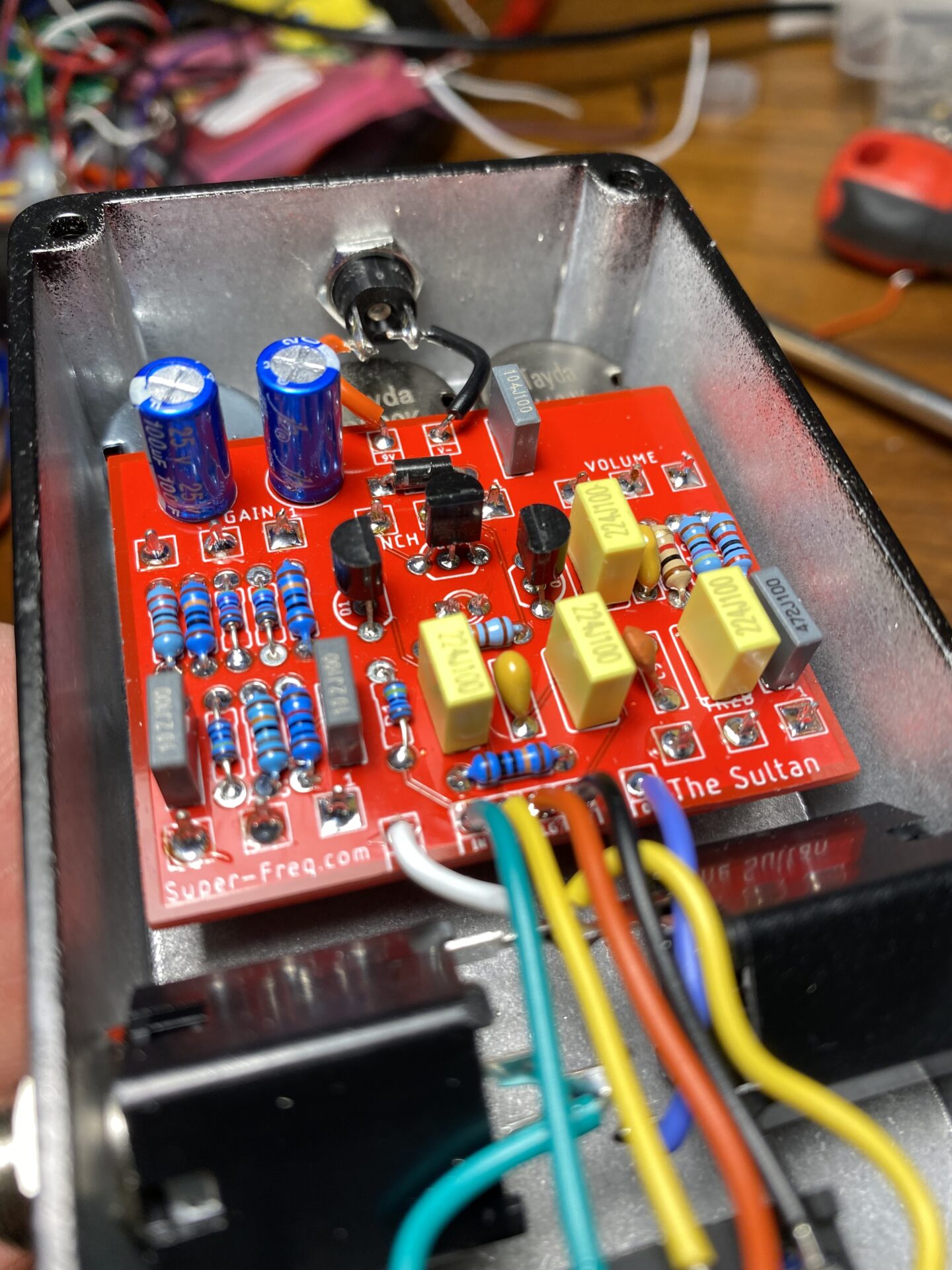

The Sultan v1.1

Heres an update to the Sultan. Read about my error in the first version of the pcb here. I made a mistake and the jacks grounds were not grounded on the first version. I ordered an updated board from PCBWay.com to move this project out of the prototype phase. This was my entry in the…

-

Mother Fuzz

This is Mic Testers Big Muff Plus. It’s a Big Muff with a JFET input and output stage, and a James control in place of the BMP tone control. The JFET input creates a higher input impedance the on the original Big Muff which prevents treble loss. Schematic Q1 is a high impedance input before…

-

Scuzz Box

This is a a second build of Distort-O-Matic XI from Stompboxology. Read more about the first version of the project here and here, and a demo. The first version of the PCB had a couple mistakes which I fixed with this board. I designed the board to fit a 1590B enclosure. In the first build…

-

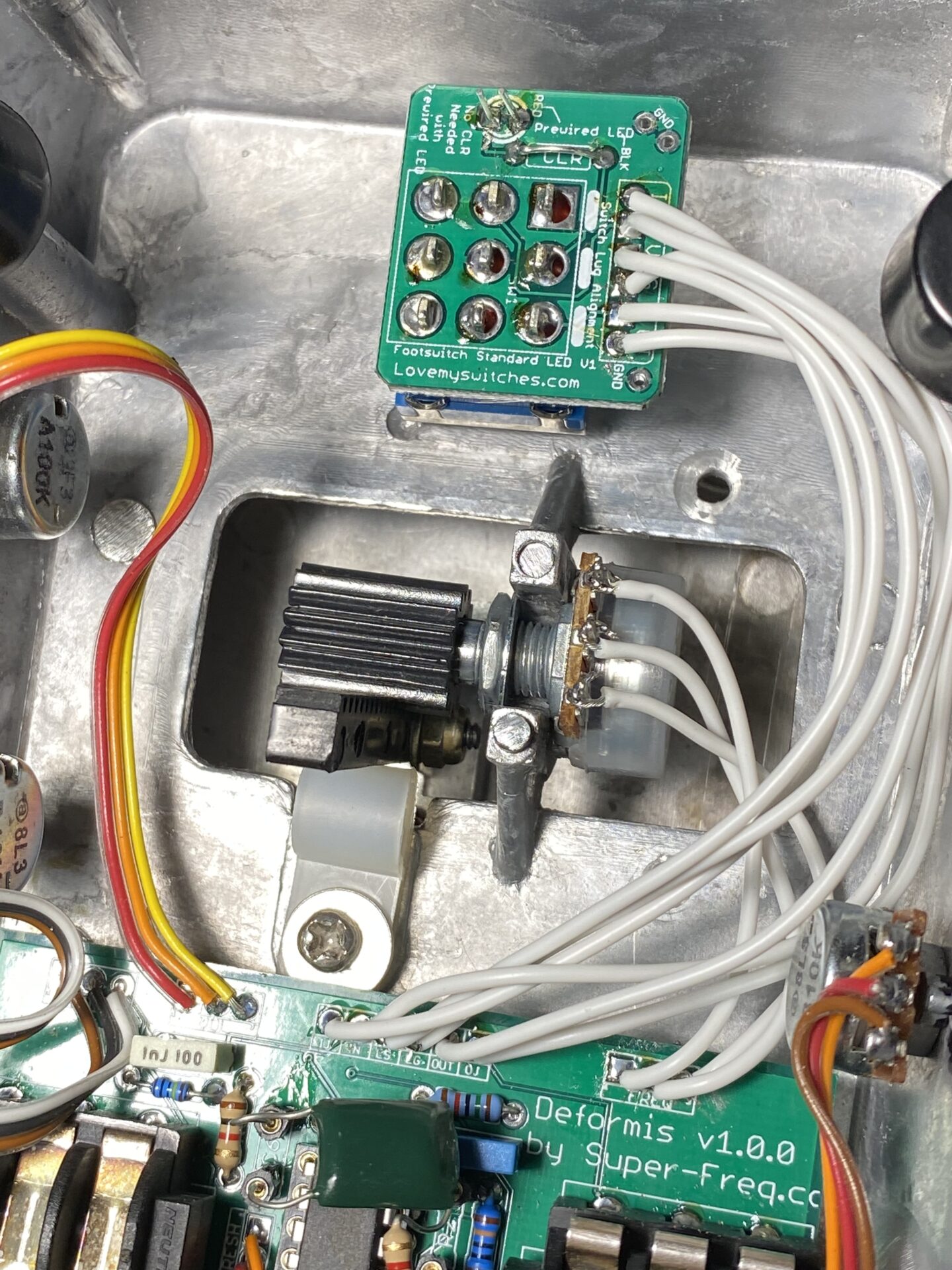

Deformis update

I worked on Deformis, see my earlier post for details and schematic. In a nutshell Deformis is my version of Tim Escobedo’s Ugly Face in a wah shell with the pedal controlling the frequency sweep. In the first pass I got everything working but, it wasn’t working well. The biggest problem was the pedal action…

-

Ugly Face Circles

I made a few small updates to Ugly Face PCB. I needed to do a build to make sure that everything is working as it should. I ordered these boards from PCBWay.com. The service is a very reasonably priced which makes them great for prototyping. I soldered up the board. This time I used a…

-

Summon Fuzz a bigger muff

This is Mic Tester’s 21st Century Big Muff. Its the standard big at it’s heart but updated. It uses an op-amp for the input and output stages, a James tone stack, and adds an interesting gain control to the clipping stages along with a diode lift switch for the first stage. I’m a Big Muff…

-

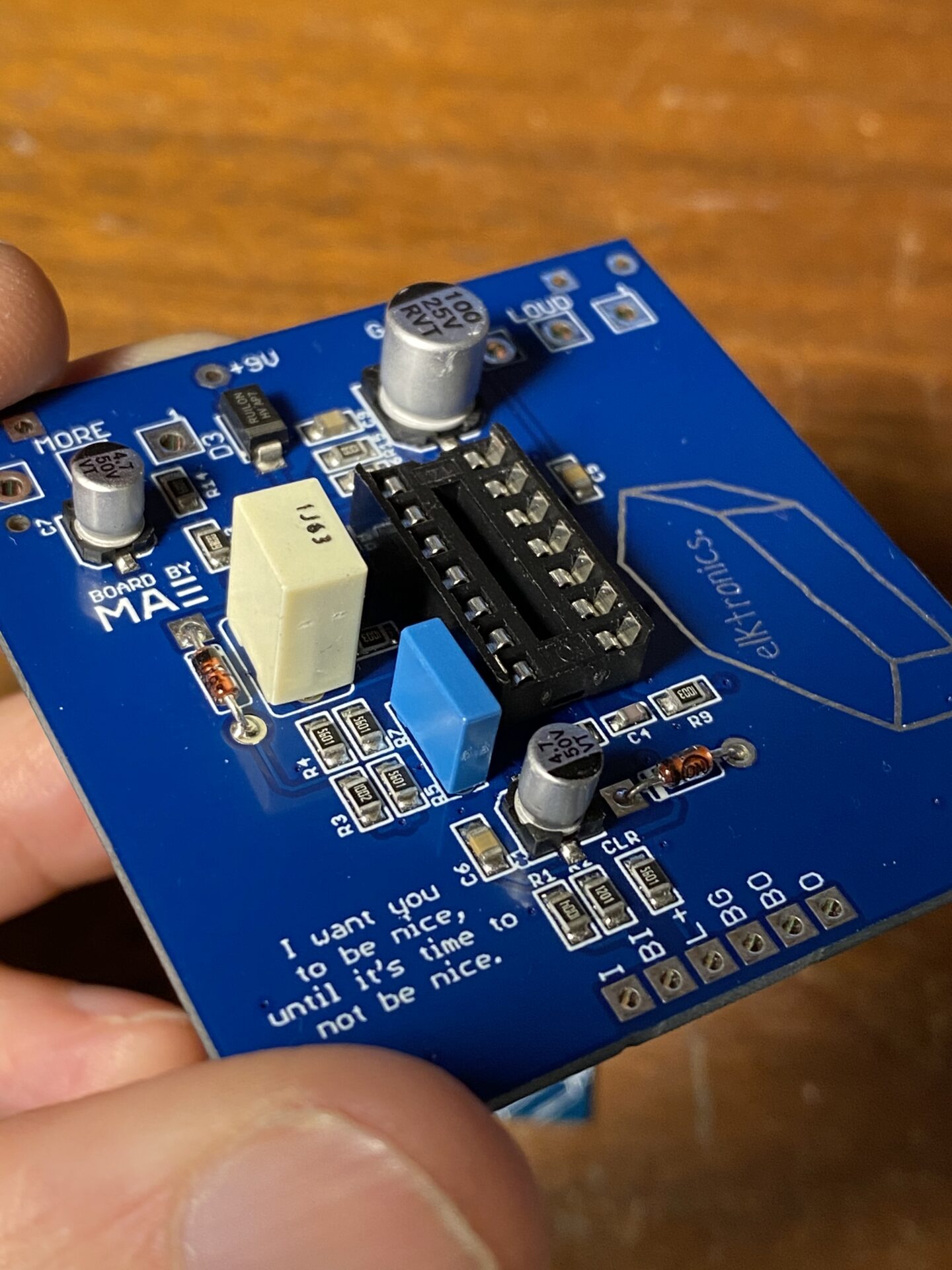

Elktronics Fuzz Build

This PCB came from Elktronics. It’s fuzz similar to the fuzz face and Tonebender built around the CA3046/3086 transistor array. Here’s a demo: The board came with all of the surface mount parts in place. I needed to add the two box caps, the two glass diodes, and the CA3046. I put a socket in…

-

Elktronics Fuzz

Here is an interesting fuzz built around the CA3046/3086 transistor array. Looks like a Fuzz Face/Tone Bender built around the low gain transistors in the 3046/3086. This is a pedal from Elktronics. Looks like they sold out of their first run of these. Here’s a demo video: Sounds pretty good! It’s got some great fuzz…

-

Scuzz Box v1.1

This is a second version of the Distort-O-Matic XI from stompboxology. You can read about the first versions here, and here. Distort-o-matic XI is described as a distortion box with an aggressive tone control. In more concrete terms it’s a diode clipper and octave fuzz with with a two band active tone control 30db of…

-

Distort-o-Matic XI demo

This is an audio demo of the Distort-o-matic XI from Stompboxology. Check out my build page for a schematic and images of the finished project.

-

The Sultan Fuzz

This is my entry in the End of Days Fuzz Challenge 2022. Based on the Fuzz Face with an added two band tone control similar to the tone controls on Orange and Ampeg amplifiers. I wrote about this circuit in this post: The Sultan. I was pretty happy with the sounds on the breadboard so…

-

Super-Fuzz V2

I updated the Super-Fuzz Board to fix a problem with the last version. The prototyping service at PCBWay.com is very inexpensive, which facilitates my workflow. The schematic I used for this project came from Freestompboxes.org. It’s based on the original with a couple mods. The Tone switch has been turned into a pot to provide a range…