-

It’s Bandcamp friday!

I’m a big fan of Bandcamp, it has everything I want in a music service, it supports consuming music by the album, and has great support for music creators. The first Friday of every month they give 100% of proceeds to the band! So today is a great day to buy some music! Here are…

-

Terrarium Rhythm Delay

I built the PedalPCB terrarium a few months ago. I Finally got around to installing some software and testing it out. I found this post on the PedalPCB forum. Sonic_explorer includes a link to a bin file for a multi-tap delay. I decided this might be a good place to start. I tried a few…

-

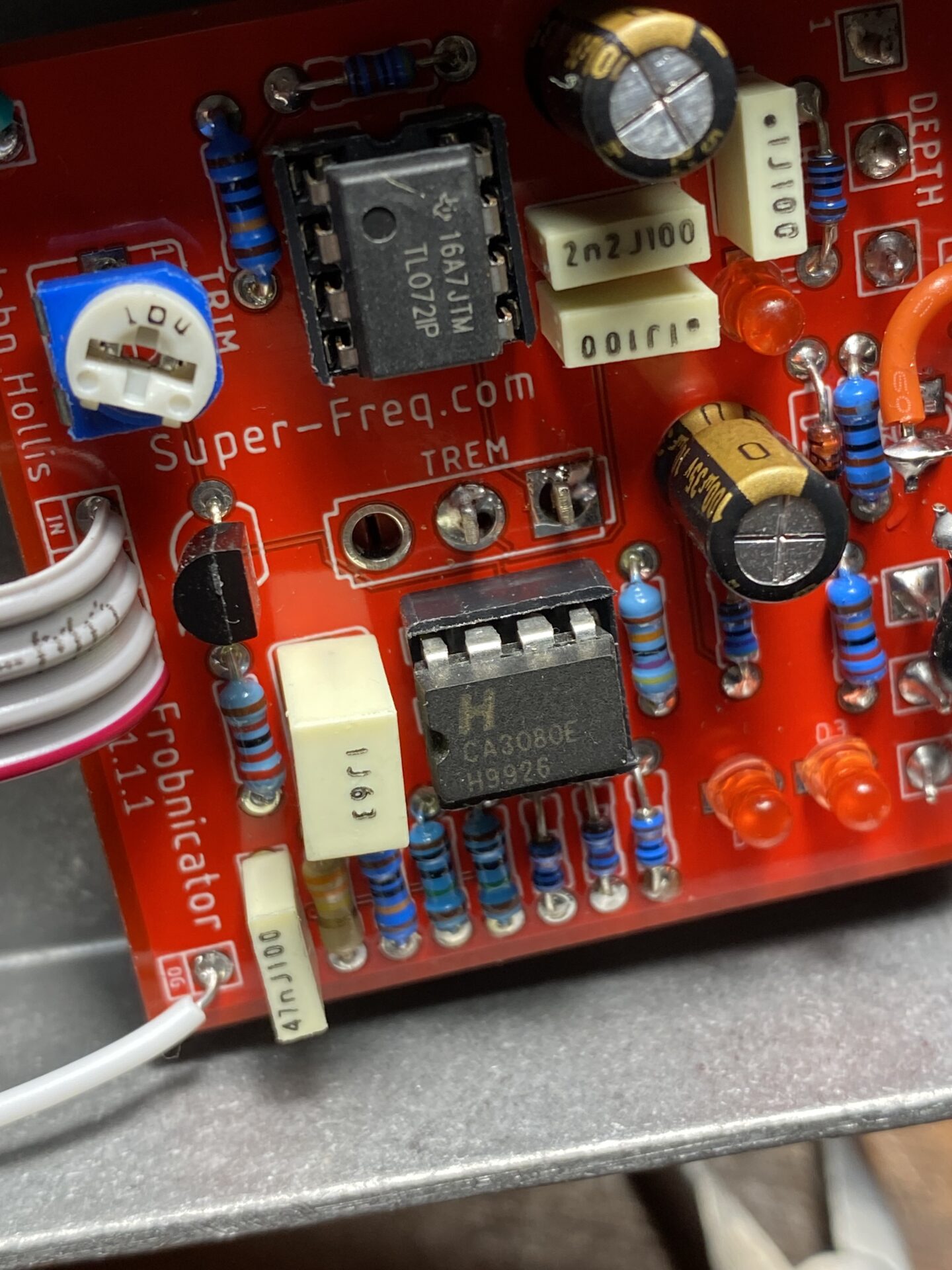

Frobnicator

This is my second try to get this right. I designed a PCB for this earlier but the errors were too great to get around. Quick overview, Frobnicator is a tremolo by John Hollis, one of the original DIY crew. He designed a few very original effects that still exist on his site. Frobinactor is…

-

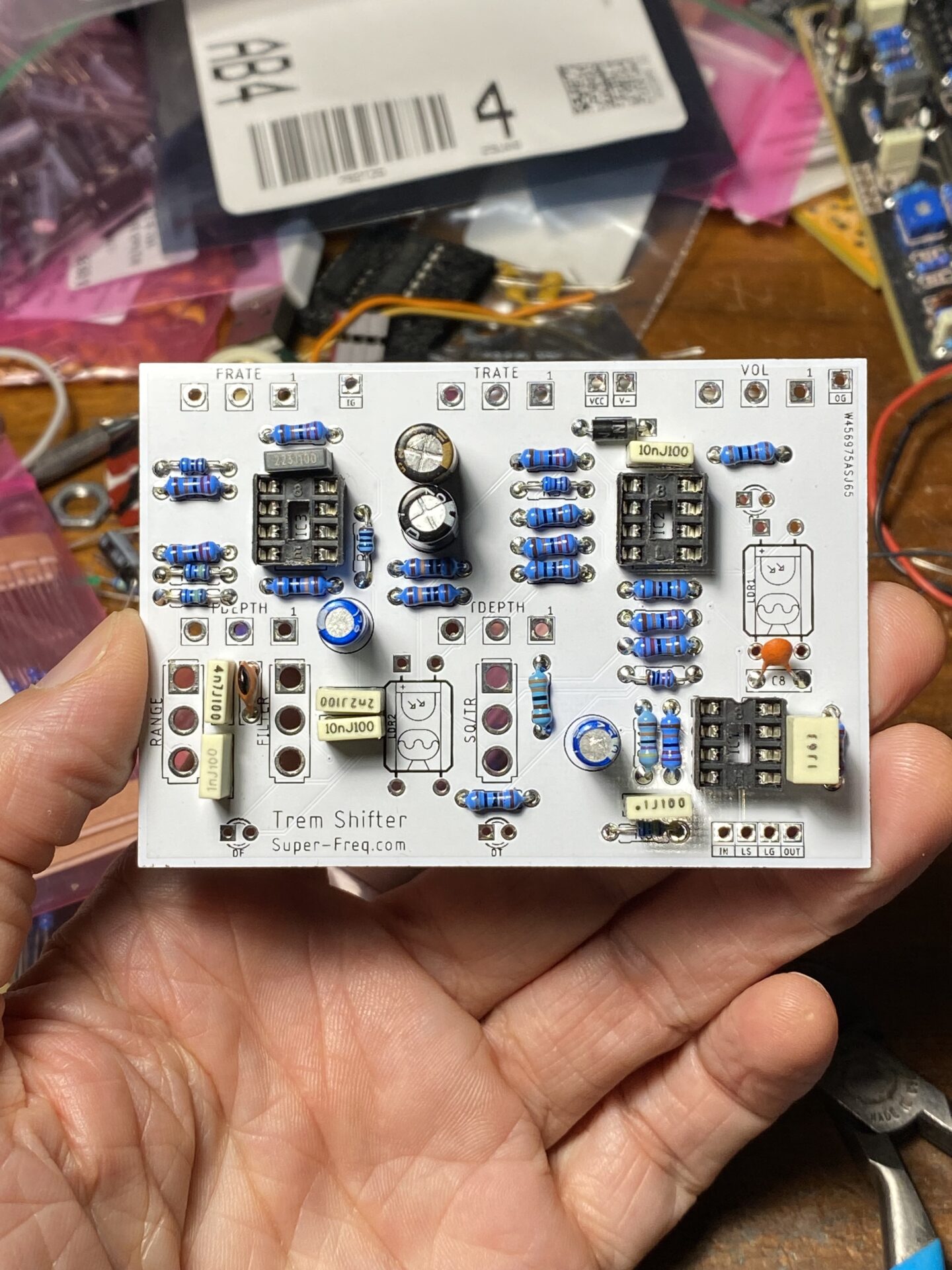

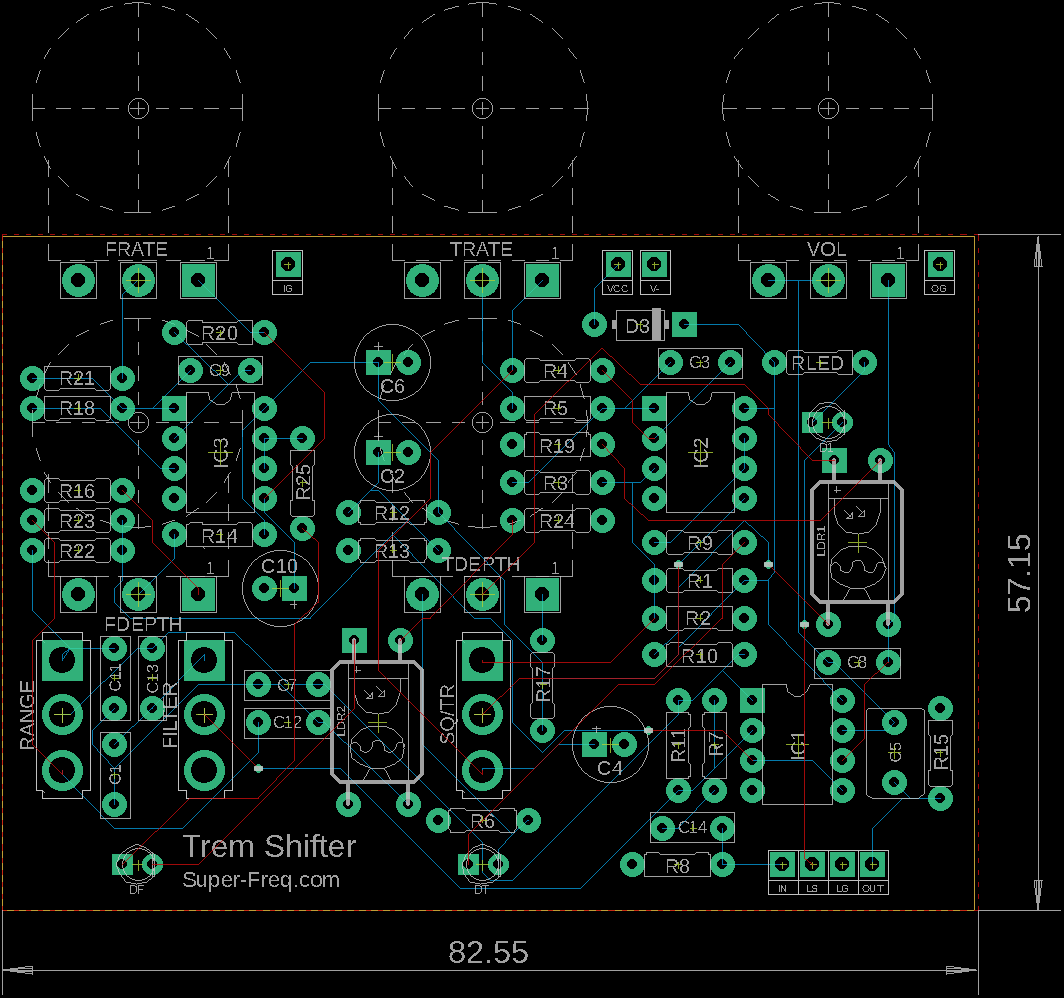

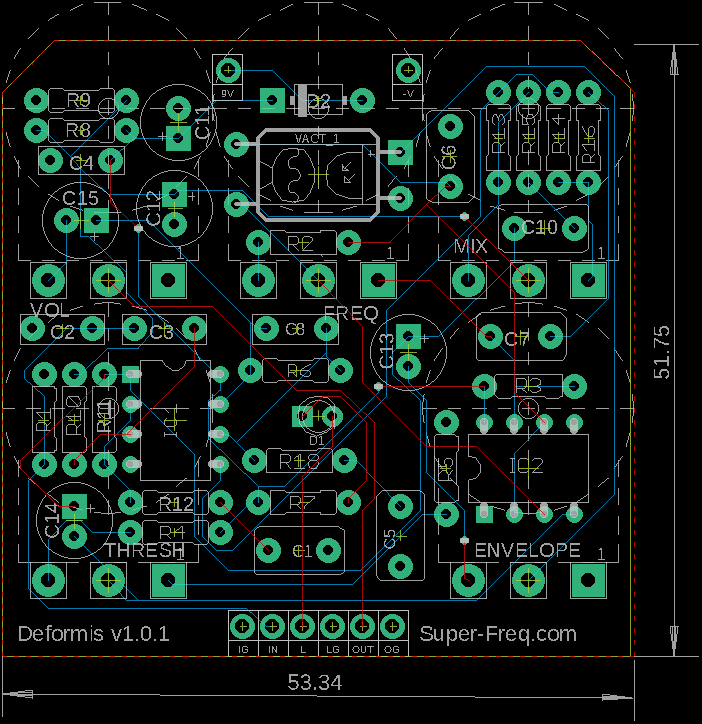

Tremshifter Build

This is a board I created for Deadastronaut’s Tremshifter. The Tremshifter is a combination tremolo and filter. It has two LFO’s, one for each the tremolo and filter, with a rate and a depth pot for each. The tremolo section has a shape switch for square and triangle. The filter section has a an on…

-

New Solder!

I have been off the pedal building thing for a little while. I ran out of solder and had to take a break. But I just ordered a new spool!

-

Trem Shifter (Dead Astronaut)

This is a redesign of the Tremshifter by Dead Astronaut FX. It’s a tremolo and filter in one. There are two LFOs, one driving each the tremolo and the filter, with a rate and depth control for each. I built a couple of the Dead Astronaut boards and they worked well. I didn’t like the…

-

EuroPi

EuroPi is a Eurorack module based on the Pico Pi. Pico Pi is similar to the Arduino Nano but is based on the Raspberry Pi. A nice feature of the Pico PI is the price, they run about $4. The Arduino Nano tends to run about $15, but you can get knock offs for about…

-

Super Frequency

This is my spin on Tim Escobedo’s Ugly Face. The original is a great DIY project anyone that hasn’t built it should give it a try. Super fun, unique sound, parts are easy to get, and it’s not a difficult built. This version makes a few changes to the original. The original uses an LM386…

-

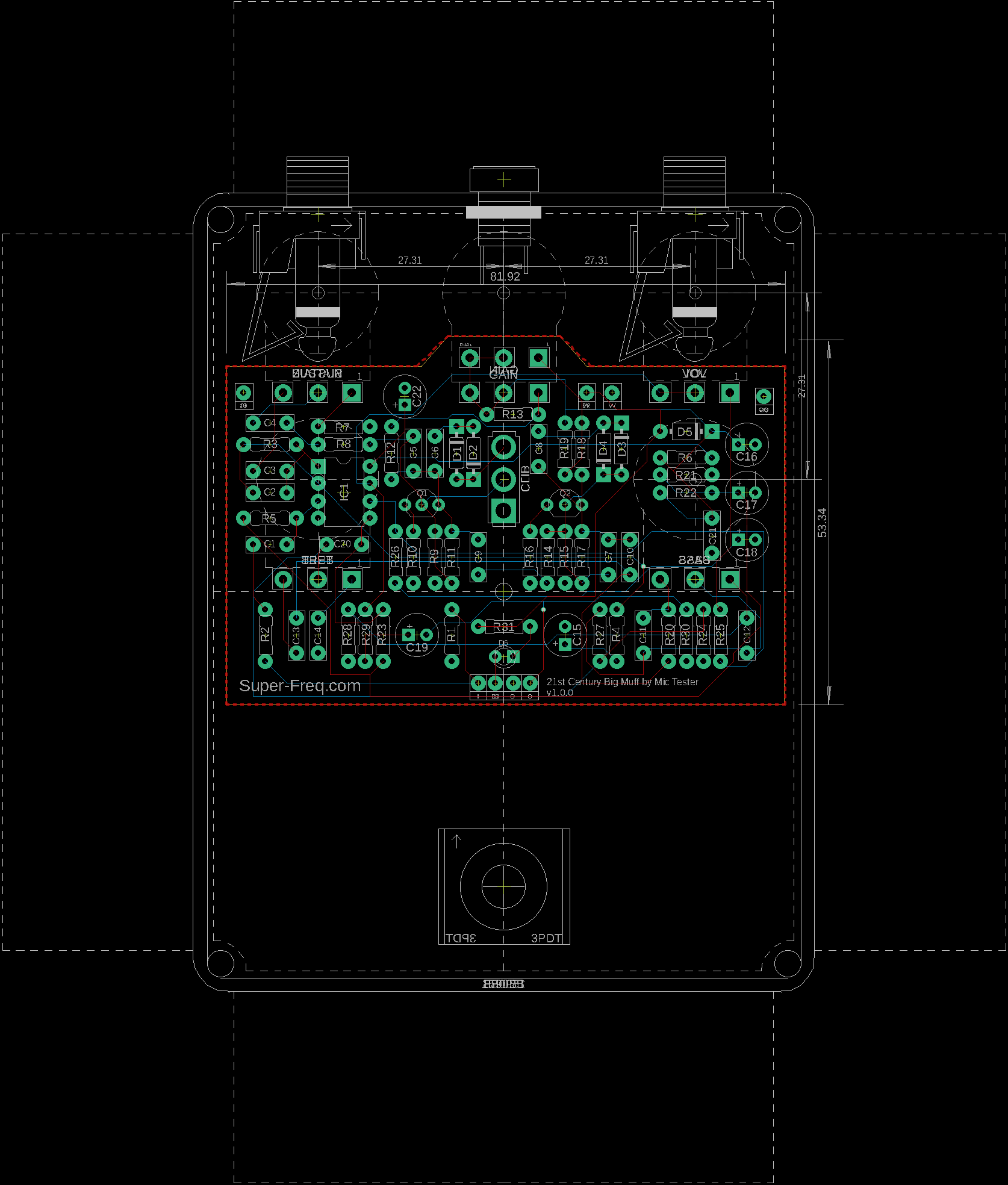

Bigger Muff part 2

Looking at the Bigger Muff. Still not happy with this, it doesn’t sound bad it’s just that the range of the controls is unsatisfying. There are plenty of usable sounds some but some of the settings are not useful. Here is the schematic: Here is a BOM: Partlist: BASS A1M 16MM GAIN A100k 16MM_DUALSUSTAIN A100k…

-

Peach Fuzz Clone

I have wanted to try the Frantone Peach Fuzz for a long time. The circuit uses one of my favorite chips the LM386. Not only does it use the 386 it uses two in series. Frantone is one of the original boutique companies, starting in 1994! They went dormant for a some years but have…

-

Peach Pit

This is my take on the Frantone Peach Fuzz. Peach Fuzz is an op-amp buffer into a pair of LM386 in series, followed by a tone control similar to the Big Muff. It uses a dual op-amp but only one of the op-amps is used. Frantone was one of the early “boutique” small name builders.…

-

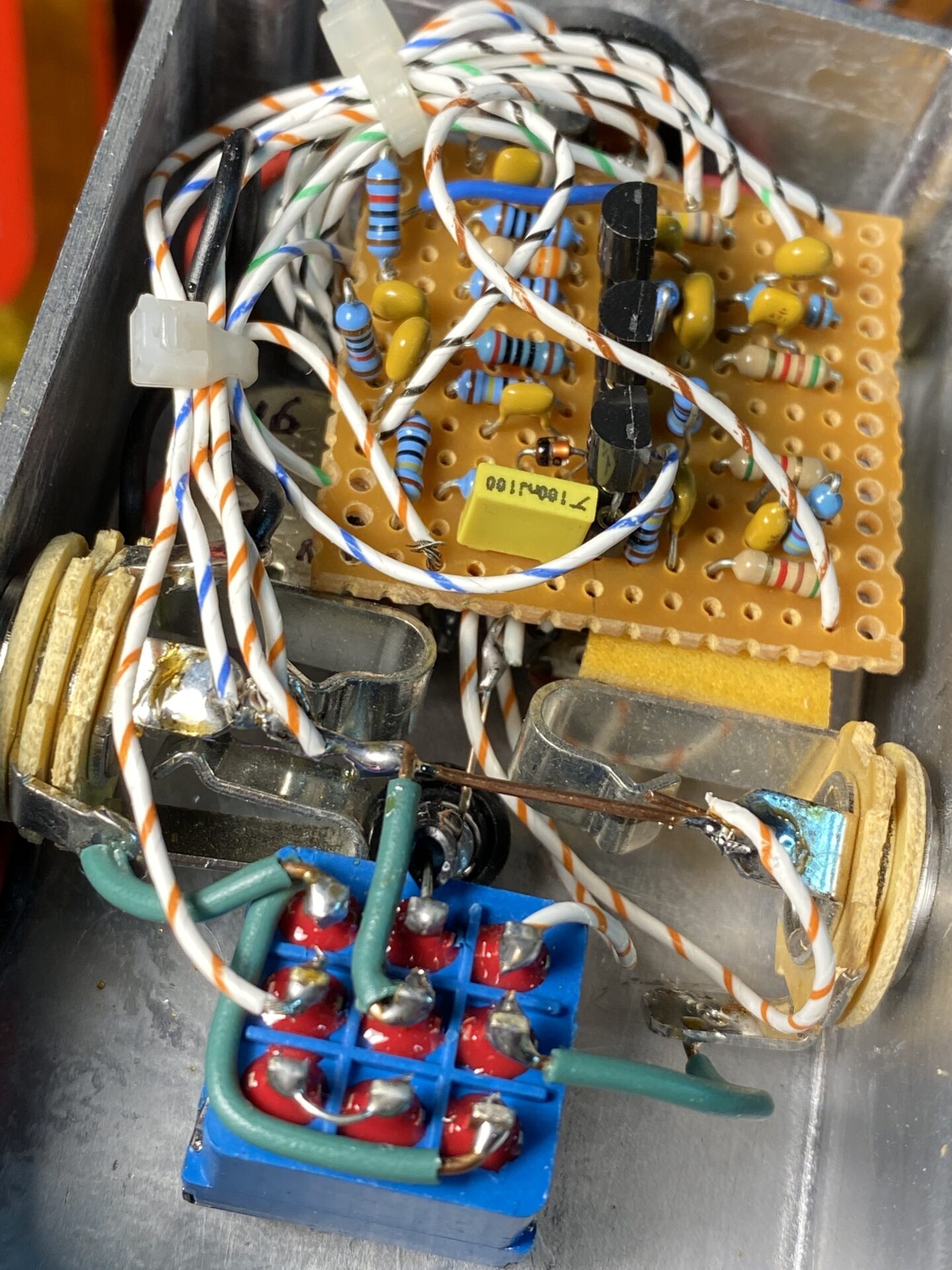

Debugging your Circuit

No matter how many pedals I build they don’t always work, at least not on the first try! Anything can go wrong. Debugging is a skill and an art, that is not hard to master. It’s impossible to name all of the possible things that can go wrong but, I can give you a list…