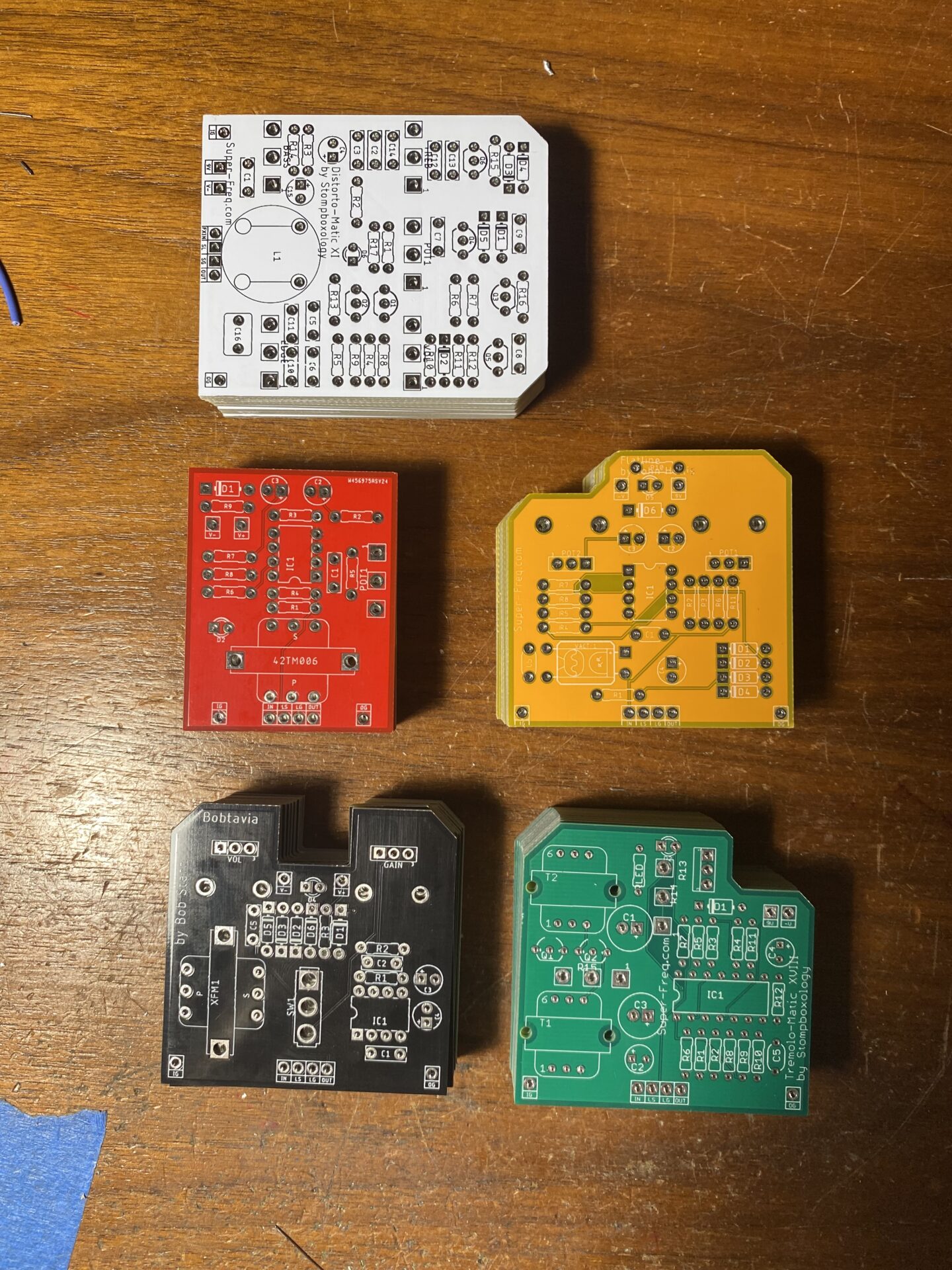

I have a few new PCB projects in the mail today.

- Flatline Compressor by John Hollis

- Titan Boost by John Hollis

- Tremolo-matic XXVIII from Stompboxology

- Distort-o-matic XI from Stompboxology

- Bobtavia by Bob Starr

John Hollis

John Hollis was one of the first people I ran into posting DIY designs on the internet. All of his designs were original and well crafted. Check out his site here. Notice all of the designs are hand-drawn!

He doesn’t shy away from challenging effects like Phase shifters, and Flangers. The Frobnicator has a ring mod mode. Many of his designs are still being built by the DIY community.

The projects I chose to make boards for were the Flatline compress and the Titan Boost. I have built both of these before and like the sounds. The Flatline is pretty popular in the DIY community, Titan Boost is less so.

The Flatline is a simple optical compressor using a dual op-amp and works with a wide range of LDRs.

The Titan boost uses a dual op-amp and step-up transformer; the transformer boosts the signal from a 9v power to 20v! The first one I built sounded good. It’s an interesting idea that may get a more dynamic range without a charge pump. The Yamaha Revstar uses a similar idea for a passive onboard boost.

Stompboxology

Stompboxology was a newsletter produced by Nicholas Boscorelli back in the early naughties. I’ve written about it before. There was a lot of great idea in these newsletters. Some were maybe over-engineered. I’m a fan of a few of these projects and have wanted to build them.

The two projects here I have never built before. These have been on my to-do list for years now.

The first is the Tremolo-magic XVIII which uses a couple transformers as the VCA.

The second project is the Distort-o-Matic XI which is more or less a Super Fuzz with an interesting tone section.

Bob Starr

I can’t say anything about Bob Starr. The Bobtavia was one of, if not, the first guitar pedals I built. It sounded great! It’s also easy to build. When I built it, Radio Shack was still in business, and you could get all of the parts for the Bobtavia from Radio Shack.

The Bobtavia is an octave up, built around the LM386 (I love this chip) and a transformer.

PCBWay.com

I designed all of these boards in Eagle and had them manufactured at PCBWay.com. This is my current favorite workflow. The costs are very reasonable and the quality of the boards excellent. Working with boards solder masked and pre-tinned is much easier and more reliable than working with handmade PCBs, or using strip-board, perf-board, or Vero-board, and also allows for smaller trace sizes which allows me to fit more onto a smaller board.

For me spending time in software planning the design is time better spent; rather For me spending time in software, and planning the design is time better spent; rather than spending time etching drilling, and debugging. Plus if I want to produce these professionally I’m already there!

Leave a Reply